Produkt Oversigt

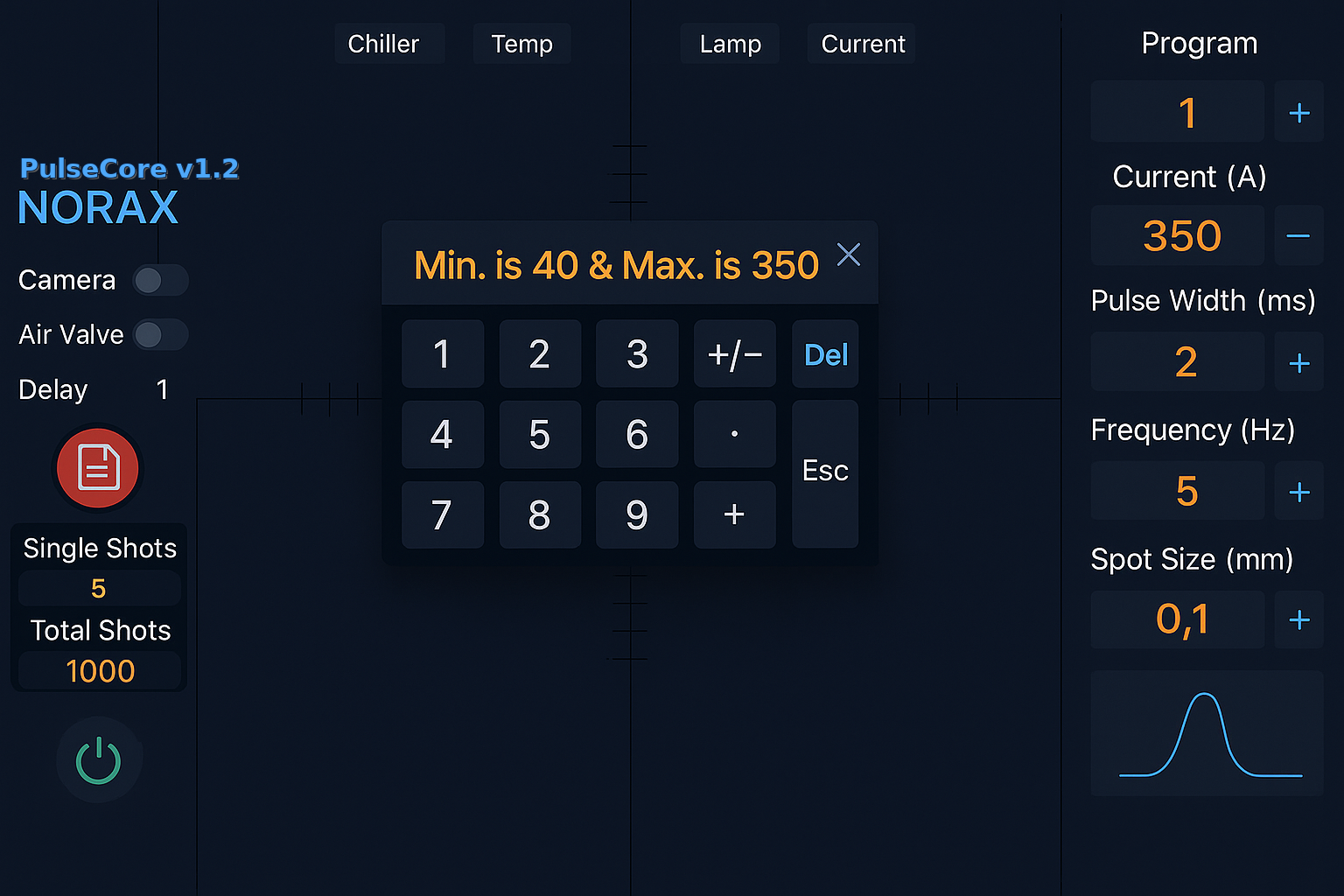

Laser welding technology, as a highly concentrated heat source, enables ultra-precise material processing across a wide range of industrial applications. Unlike conventional welding methods, laser welding is a non-contact process that directs localized heat exclusively to the weld zone. This dramatically reduces thermal distortion and preserves the structural integrity of delicate or heat-sensitive components. The NORAX laser welding system empowers operators to work with complete confidence-without the risk of thermal injury-while maintaining full visual control of the welding area through an integrated microscope or high-definition display. To meet the demands of continuous industrial workflows, NORAX is built around a high-performance cooling system that guarantees stable, uninterrupted operation-even during extended use. Its reinforced, durable construction makes it ideal for high-volume production environments that require 24/7 reliability under challenging conditions. Equipped with intuitive, user-friendly software, NORAX offers refined control over all essential welding parameters, including pulse energy, frequency, and spot size. This level of adjustment allows users to precisely match the welding process to different materials, joint geometries, and application complexities-ensuring clean, uniform welds with exceptional consistency and surface quality